One of the methods of determining an organizations approach to its business is to evaluate its workplace organization capability & visual management standards.

5S engages people through the use of ‘Standards’ and ‘Discipline’.

It is not just about housekeeping, but concentrating on maintaining the standards & discipline to manage the organization – all achieved by upholding & showing respect for the Gemba [workplace] every day.

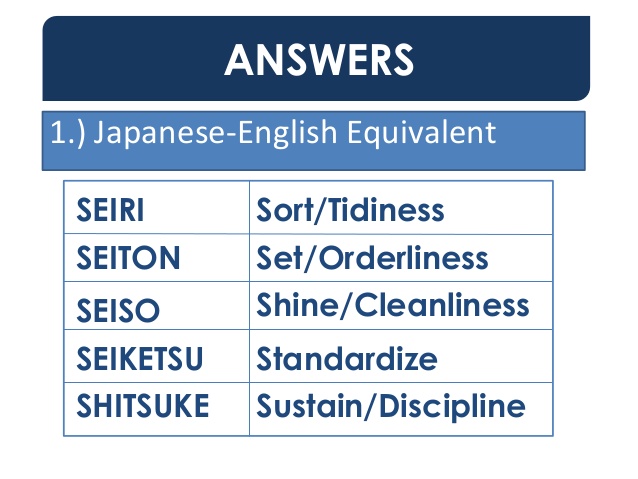

The 5 Steps are as follows:

- Sort: Sort out & separate that which is needed & not needed in the area.

- Straighten: Arrange items that are needed so that they are ready & easy to use. Clearly identify locations for all items so that anyone can find them & return them once the task is completed.

- Shine: Clean the workplace & equipment on a regular basis in order to maintain standards & identify defects.

- Standardise: Revisit the first three of the 5S on a frequent basis and confirm the condition of the Gemba using standard procedures.

- Sustain: Keep to the rules to maintain the standard & continue to improve every day.

Benefits of 5S workplace organization

5S relates to workplace organization and forms a solid foundation upon which many organizations base their drive for continuous improvement. It is equally applicable & successful in all sectors helping to achieve high impact results.

It is a systematic and methodical approach allowing teams to organise their workplace in the safest and most efficient manner.

The discipline to check & repair equipment is included & adopted. The entire process is managed through the use of team generated audit documents, completed on an agreed frequency by responsible owners within the Gemba.

Summary

- Improved safety

- 5S becomes a fundamental business measure & key driver for Kaizen

- Forms a solid foundation upon which to build continuous improvement

- Employees gain a sense of ownership, involvement & responsibility

- Reduction in waste – as defined by Ohno’s seven forms of waste

- Improved performance in productivity, quality & morale leads to increased profitability